Miniature motors are small electric motors that convert electrical energy into mechanical energy. Miniature motors are used where larger motors cannot fit. A small motor ranges from 1.24 inches in length and 0.511 inches in diameter. At 8,000 rpm, it is capable of 2.5 W of output power. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Carter Motor has over 70 years of experience in quality electric motor manufacturing. Some of the motors manufactured include, AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, along with many others. All of our products are designed and assembled in the United States by our dedicated team of engineers.

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Miniature Motor Manufacturers

Miniature Motors: Types, Applications, Benefits, and How to Choose the Right Supplier

Miniature motors, often referred to as micro motors or small electric motors, are compact, high-efficiency devices engineered for use in a wide range of applications where space, weight, and precision are critical factors. Built with advanced technologies such as Neodymium magnets, precious metal brushes, and rhombic-wound moving-coil rotors, these miniature motors offer maximum winding density and exceptional power-to-weight ratios. With gear ratios spanning from 4:1 to over 1,100:1, continuous torque capacities up to 0.35 Nm, and intermittent torque up to 0.53 Nm, miniature motors are a crucial component in today’s high-performance, space-constrained products and devices. Their compact size and efficiency make them a preferred solution across industries like robotics, medical devices, automation, aerospace, automotive, consumer electronics, and more.

What Is a Miniature Motor?

A miniature motor is a small-sized electric motor designed to provide precise motion control, efficient power transmission, and low energy consumption in limited-space applications. Miniature motors are engineered to offer superior torque, speed control, and reliability while minimizing size and weight. Many micro motors are constructed using lightweight materials and advanced magnetic configurations to maximize the power-to-weight ratio, reduce losses, and enhance overall performance.

Key Characteristics of Miniature Motors

- Compact and lightweight design for integration into space-restricted devices

- High torque and efficiency relative to size

- Low heat generation and minimal energy loss

- Precision control of speed and position

- Long operational lifespan and reliability

- Customizable voltage, shaft, and gear configurations

Types of Miniature Motors

Miniature motors come in several core varieties, each suited to particular applications and performance requirements. Understanding the differences between these types will help you select the optimal solution for your specific use case. Below, we explore the main miniature motor types, their advantages, and typical applications.

Brushed Miniature DC Motor

Brushed miniature DC motors are widely used in both large and small devices due to their simplicity, cost-effectiveness, and robust performance. These motors operate with direct current (DC) power and use brushes to transfer electrical current to the spinning armature. Key benefits include low friction, low starting voltages, negligible iron losses, high efficiency, effective thermal dissipation, and a linear torque-speed relationship. Brushed DC motors are especially valued for their outstanding speed-to-torque performance and minimal joule heating, making them a popular choice for battery-powered devices, toys, small appliances, and industrial automation systems.

Common Applications for Brushed Miniature DC Motors

- Portable medical equipment (e.g., infusion pumps, ventilators)

- Consumer electronics (e.g., electric shavers, cameras)

- Automotive actuators and HVAC controls

- Industrial automation and robotics

- Precision instrumentation and laboratory devices

Miniature Brushless DC Motor (BLDC)

Miniature brushless DC motors, also known as BLDC motors, represent a significant technological advancement over traditional brushed motors. These motors eliminate the need for brushes, relying instead on electronic commutation for smooth operation. BLDC miniature motors are available in both slotted and slotless configurations, each offering distinct performance advantages. Slotted BLDC motors utilize stators with windings and laminations, providing high torque density. Slotless BLDC motors use ironless cylindrical windings for extremely low cogging and high efficiency. Key benefits include precise position control, superior speed regulation, high torque output, low maintenance, and an extended operational lifespan. Miniature BLDC motors are increasingly favored in applications demanding reliability, minimal noise, and high performance.

Typical Applications for Miniature Brushless DC Motors

- Medical devices (e.g., surgical power tools, prosthetics, insulin pumps)

- Advanced robotics (e.g., collaborative robots, hobby drones)

- Precision optical equipment and camera gimbals

- 3D printers and automated laboratory instruments

- Electric vehicles and e-mobility systems

Miniature Stepper Motor

Miniature stepper motors are specialized motors designed for applications that require rapid, incremental, and highly precise motion control. Unlike typical permanent magnet stepper motors, these advanced micro steppers leverage innovative technologies such as single thin disc magnets, resulting in shorter magnetic circuits and reduced iron losses. This allows for higher acceleration and dynamic performance compared to traditional steppers. Miniature stepper motors are ideal for applications involving synchronized multi-axis movements, positioning, and repeatable actuation, such as pick-and-place machines and medical automation.

Use Cases for Miniature Stepper Motors

- Automated laboratory dispensers and analyzers

- Precision medical pumps and diagnostic devices

- Jewelry and watchmaking equipment

- Miniaturized robotics and mechatronics

- Camera focus and zoom systems

Other Common Types of Miniature Motors

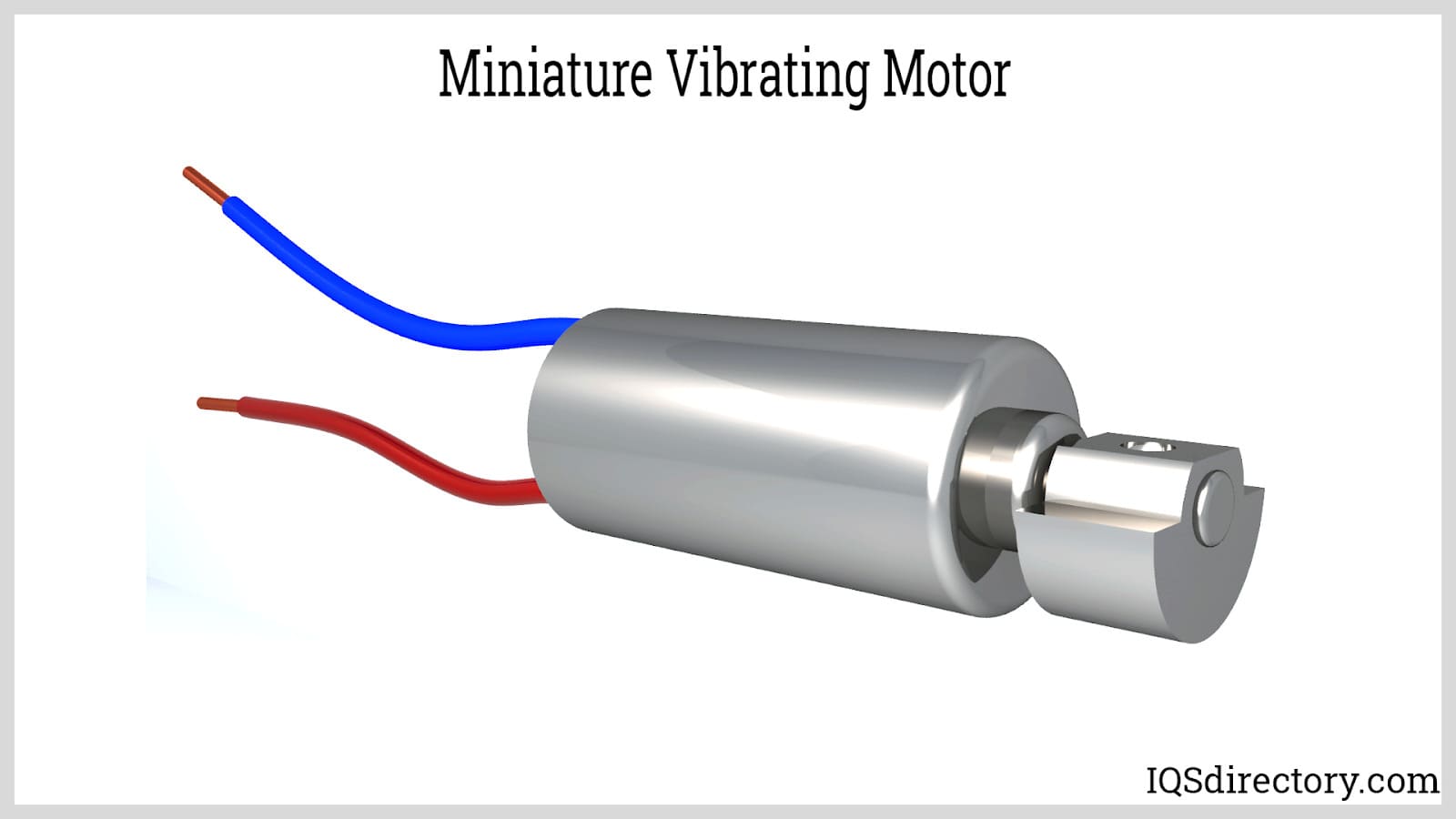

- Coreless DC miniature motors for ultra-lightweight applications

- Miniature vibration motors for haptic feedback in mobile devices

- Linear miniature motors for direct linear actuation

- Miniature servo motors for closed-loop control and precision positioning

- Piezoelectric miniature motors for silent, high-accuracy movements

Miniature Motor Features and Technical Specifications

Selecting the right miniature motor requires careful consideration of key features and technical parameters. Below, we summarize the main features and explain how they impact performance and suitability for various applications.

- High Efficiency: Miniature motors are engineered to convert electrical energy into mechanical power with minimal losses, supporting energy savings and reduced operating costs.

- Speed Variability: The ability to operate at variable speeds enables precise control and adaptability for different tasks.

- Speed Control: Most miniature motors can be paired with electronic controllers to deliver fine-tuned speed adjustments, essential for automation and process control.

- Low Price: Mass production and streamlined manufacturing make miniature motors a cost-effective choice for OEMs and end-users alike.

- High Quality: Stringent quality controls and advanced manufacturing techniques ensure consistent performance and reliability.

- High Reliability: Designed for long life cycles, miniature motors offer dependable operation in demanding environments.

- Communication: Many modern miniature motors can be integrated with digital communication protocols for remote monitoring and diagnostics.

- Small Dimensions: Their compact size allows seamless integration into tight spaces and portable devices.

- Light Weight: Lightweight designs are ideal for handheld, wearable, and mobile applications.

- Customizability: Options for shaft length, mounting, voltage, and gear ratios to match application-specific needs.

Typical Technical Specifications

- Voltage range: 1.5V to 48V

- Rated speed: 100 RPM to 100,000+ RPM

- Torque: 0.01 Nm to 1 Nm or higher

- Motor diameter: 1 mm to 50 mm

- Operating temperature: -20°C to 85°C

Applications of Miniature Motors

Miniature motors are the backbone of many modern innovations, powering devices and systems across diverse sectors. Their combination of small size, high efficiency, and reliability makes them indispensable in applications ranging from industrial automation to consumer gadgets.

Industrial Automation and Robotics

- Industrial robots: Miniature motors allow industrial robots to execute rapid, precise movements. As motor efficiency and power density increase, robots become lighter, more agile, and energy-efficient. This leads to improved process flexibility, reduced cost of ownership, and increased automation ROI for manufacturers.

- Pick and place assembly: Pick-and-place (P&P) equipment, commonly used in electronics manufacturing, relies on miniature motors for fast, accurate part handling. Compact motors fit within robotic arms, enabling high-speed operations and millions of cycles without failure.

- Material handling: Automated material handling systems use miniature motors to move, sort, and stack goods efficiently. By occupying less space and consuming less power, these motors lower overall system footprint and operational expenses.

- Conveyor systems: Micro motors enable conveyor systems to transport heavy or delicate loads within compact footprints, expanding system design possibilities and improving throughput.

Textile and Manufacturing Equipment

- Yarn winding machinery: Precision motion is vital in textile processes. Miniature motors provide the controlled movement needed to wind yarn without tangling, ensuring consistent quality and minimizing material waste. Small motors are widely adopted in textile automation.

- Precision assembly: From medical device manufacturing to microelectronics assembly, miniature motors deliver the accuracy and repeatability required for automated, high-throughput production lines.

Medical Devices and Healthcare

- Miniature motors are essential in life-saving medical equipment, such as infusion pumps, ventilators, prosthetic devices, and surgical robots. Their reliability, quiet operation, and compact size enable advanced healthcare solutions that improve patient outcomes and enable innovative treatment modalities.

- Diagnostic equipment, laboratory automation, and portable medical instruments rely on micro motors for precise motion control and dependable operation.

Consumer Electronics and Wearables

- Smartphones and tablets use miniature vibration motors for haptic feedback.

- Wearable fitness devices, smartwatches, and hearing aids depend on micro motors for subtle actuation and low power consumption.

- Camera autofocus and zoom systems utilize miniature motors for fast, quiet, and accurate lens positioning.

Automotive and Aerospace Applications

- Miniature motors are integrated into automotive actuators, adaptive lighting systems, mirror adjustments, and seat controls.

- In aerospace, their lightweight and reliable design supports avionics, UAV actuation, and satellite mechanisms where every gram counts.

Emerging and Specialized Applications

- Miniature motors now power innovations in robotics, Internet of Things (IoT) devices, microfluidics, and laboratory automation.

- In research and development, engineers use miniature motors to prototype and test new mechatronic systems with high precision.

Benefits of Using Miniature Motors

- Space Savings: Enable compact product designs and portable devices.

- Energy Efficiency: Reduce power consumption and operational costs.

- Precision Control: Achieve accurate, repeatable movements for automation and robotics.

- Low Noise and Vibration: Suitable for medical, laboratory, and consumer environments.

- Extended Service Life: Low-wear designs minimize maintenance and downtime.

- Design Flexibility: Wide range of sizes, voltages, and configurations for diverse applications.

- Cost Effectiveness: Economical solutions for high-volume manufacturing or specialized projects.

How to Choose the Right Miniature Motor

Evaluating and selecting the best miniature motor for your application involves considering several critical factors. To ensure peak performance, reliability, and value, follow these steps:

- Define Your Application Requirements: What torque, speed, voltage, and size constraints must the motor meet? Are there environmental or reliability considerations?

- Select the Appropriate Motor Type: Depending on your need for precision, efficiency, or cost, choose between brushed DC, brushless DC, stepper, or specialty miniature motors.

- Consider Integration Needs: Will the motor need a gearbox, encoder, controller, or special mounting configuration?

- Evaluate Performance-to-Cost Ratio: Balance upfront cost with long-term efficiency, service life, and maintenance requirements.

- Ensure Compliance and Quality: Confirm certifications (such as ISO, CE, or RoHS) and supplier quality standards.

Common Questions When Selecting Miniature Motors

- What are the key differences between brushed and brushless miniature motors?

- How do I determine the required torque and speed for my application?

- What are the best miniature motors for battery-powered devices?

- Can I customize shaft length or mounting options?

- How do I integrate a miniature motor with my existing system?

- What maintenance is required for miniature motors?

- Are there miniature motors suitable for harsh or extreme environments?

- What is the average lead time and minimum order quantity?

Choosing the Correct Miniature Motor Supplier

Choosing a reliable miniature motor supplier is crucial for the success of your project or manufacturing process. The right supplier offers not only high-quality products but also technical support, customization options, and fast delivery. Here’s how to identify the best miniature motor partner for your needs:

- Supplier Reputation: Research suppliers with proven track records in your industry. Look for customer reviews, case studies, and certifications.

- Product Range: Does the supplier offer a comprehensive selection of miniature motors, accessories, and value-added services?

- Technical Support: Leading suppliers provide engineering guidance, customization, and rapid prototyping to help tailor solutions for your application.

- Global Reach and Logistics: Consider suppliers with international distribution and robust supply chains for uninterrupted delivery.

- Competitive Pricing: Compare costs, lead times, and volume discounts to ensure value for your investment.

To ensure the most beneficial outcome when purchasing miniature motors from a miniature motor supplier, it is important to compare several companies using our directory of miniature motor suppliers. Each miniature motor supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each miniature motor company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple miniature motor businesses with the same form.

Ready to Find Your Miniature Motor Solution?

Browse our miniature motor supplier directory to compare leading manufacturers, request quotes, and access technical resources to help you choose the right micro motor for your application.

Frequently Asked Questions (FAQs) About Miniature Motors

What is the smallest size miniature motor available?

Miniature motors can be manufactured with diameters as small as 1 mm, making them suitable for micro-robotics, medical implants, and ultra-compact electronics.

Can miniature motors be customized for specific applications?

Yes, many suppliers offer custom options for shaft dimensions, windings, gear ratios, connectors, and enclosures to meet unique project requirements.

What are the most energy-efficient miniature motors?

Brushless DC and coreless DC miniature motors typically offer the highest energy efficiency, making them ideal for battery-powered and portable devices.

How do I connect a miniature motor to my control system?

Most miniature motors can be integrated with off-the-shelf or custom motor controllers. Ensure compatibility with your voltage, current, and communication protocol requirements.

Where can I get technical support for miniature motor integration?

Contact your miniature motor supplier for engineering support, or explore online resources and technical forums dedicated to micro motor applications and troubleshooting.

Explore Further

- Small Motors: Understand the differences between small, micro, and miniature motors.

- Stepper Motors: Dive deeper into stepper motor technology, applications, and suppliers.

Conclusion: Unlock Innovation With Miniature Motors

Miniature motors are at the forefront of modern engineering, enabling breakthroughs in automation, healthcare, electronics, and more. Whether you are designing a next-generation medical device, developing a new consumer gadget, or seeking to automate precision manufacturing, choosing the right miniature motor and supplier is critical to your project’s success. Explore our resources, connect with leading suppliers, and leverage expert support to unlock your innovation potential today.

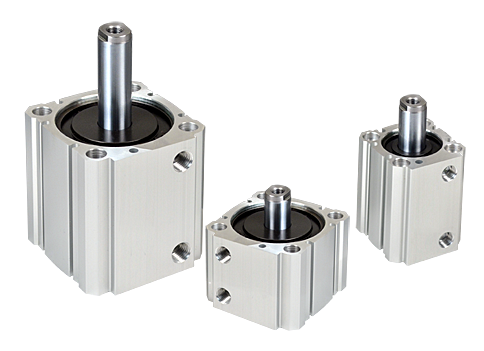

Air Cylinders

Air Cylinders Assembly Machinery

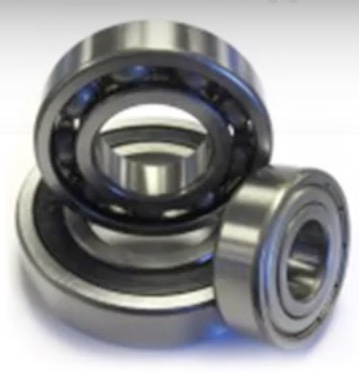

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

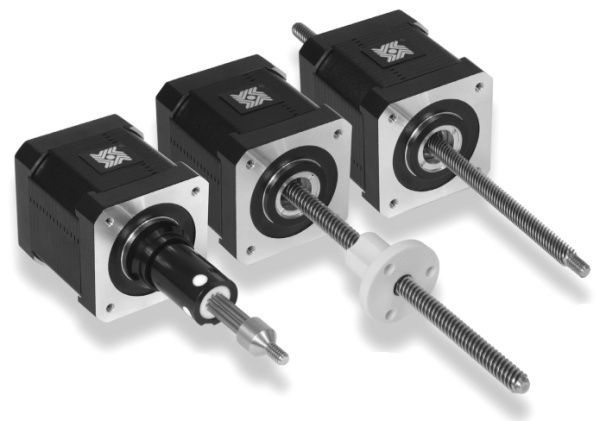

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services