A tiny electric motor is an example of an electromechanical device that converts electrical energy into mechanical energy. The motor’s output energy is used to move materials, power compressors, and rotate fans. Electric motors are powered by alternating current sources like electric generators, power grids, inverters, or direct current sources like batteries, rectifiers, and motor vehicles. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Allied Motion Technologies is a leading designer and manufacturer of high-quality fractional horsepower motors, DC motors, AC motors and much more. Focused exclusively on serving the motion control market, we serve commercial, aerospace and defense markets. For more information about Allied Motion Technologies` excellent motors, please give us a call or visit our website!

Johnson Electric is a major manufacturer of fractional horsepower motors, permanent magnet motors, stepper motors and gearboxes. We offer new solutions for the automobile industry, which provide our customers with both security and satisfaction. We've served a variety of industries since 1920.

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Small Electric Motor Manufacturers

Components of Electric Motors

Electric motors are comprised of a rotor, stator, an air gap, windings, and a commutator.

Rotor

A rotor is a moving component in a motor, generator, or alternator's electromagnetic system. Inside a motor, a rotor will rotate a shaft to generate mechanical energy. Typically, the rotor has conductors positioned to store currents and interact with the stator's magnetic field. When the rotor spins, the magnetic fields and windings will interact and produce torque at the rotor axis.

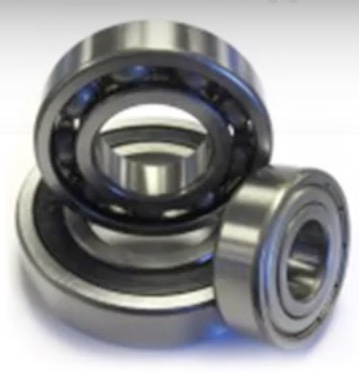

Bearings

The motor’s bearings are crucial because they support the rotor's ability to rotate around its axis. By adapting the bearings to the load of the motor, the shaft of the electric motor can be made longer. Overhung loads are those that have load forces applied to the bearing's exterior side.

Stator

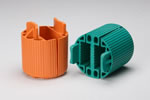

The stator is a dormant component of the motor's rotational system. It can be found in sirens, biological rotors, mud motors, and generators. A stator is made of permanent magnets, windings, or thin metal sheets known as laminations. These are employed to cut down on energy losses. The rotating armature of a motor is driven by a magnetic field that rotates around the stator.

Air Gap

The air gap in a motor refers to the space between the rotor and stator. The space has the biggest impact on the air gap effect. It is the main cause of the motor's poor power factor. As the distance between the rotor and stator widens, the magnetizing current will grow.

Windings

Windings are just wires inserted into the coils. They are encircled by a flexible iron magnetic core to create magnetic poles activated by the current. Copper windings are frequently used in motors because they effectively transport electrical load.

Commutator

A rotating electrical switch called a commutator reverses the direction of current flow between the rotor and the external circuit. The commutator is constructed using a cylinder that is assembled from several metal contact points on the machine's revolving armature. The commutator, which is made of copper and has the appearance of a half ring, is used to join the brushes to the coil.

How Small Electric Motors Function

An electric motor uses electromagnetic induction to function. A loop is created using a small conducting wire and placed between two magnets. the ends of the loop are then attached to battery connections.

Small Electric Motor Types

Small electric motors can be categorized based on power source, construction, and application. In addition to AC and DC motors, other available types of motors, include brushed, brushless, 1-phase, 2-phase, or 3-phase, air-cooled/liquid-cooled motors. General electric motors with typical characteristics and dimensions provide adequate mechanical power for industrial use.

- Small AC Electric Motors

- Small DC Electric Motors

Small AC Electric Motors

The tiny AC electric motor's primary job is to use electromagnetic induction to convert alternating current to mechanical current. The rotor and stator are the two primary components. The stator is the motor's stationary component, while the rotor spins. Small AC electric motors can have one or three phases. Three-phase motors are used for large power conversion, while single-phase motors are used for minor power conversion.

Small DC Electric Motors

A small DC electric motor is an electric rotational device that transforms DC energy into mechanical energy. The majority of motors rely on the magnetic field's generated forces. These motors' internal mechanisms, which alter the direction of current flow, are either electrical or electromechanical. The motor speed can be regulated by changing the potency of the current or the supply voltage within the field windings.

Small Electric Motor Advantages

- In comparison to other engines powered by fossil fuels, the price of these motors is low. The horsepower (hp) rating, however, is comparable for both.

- Electric motors have a longer lifespan.

- Electric motors can be automated for specific uses.

Uses For Electrical Motors

The following are some of the applications for electrical motors.

- These motors are used in rolling mills, compressors, alternators, fans, blowers, pumps, turbines, ships, tools used in machines, movers, and paper mills.

- These are the most crucial parts of automobiles, home appliances, and HVAC (heating, ventilation, and air conditioning) equipment.

- Industrial machinery such as mills, forklift trucks, letches, robots, winches, and hoists employ small electric motors.

Choosing the Proper Small Electric Motor Manufacturer

To ensure you have the most productive outcome when purchasing small electrical motors from a small electric motor manufacturer, it is important to compare several companies using our directory of small electric motor manufacturers. Each small electric motor manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each small electric motor business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple small electric motor manufacturers using the same form.

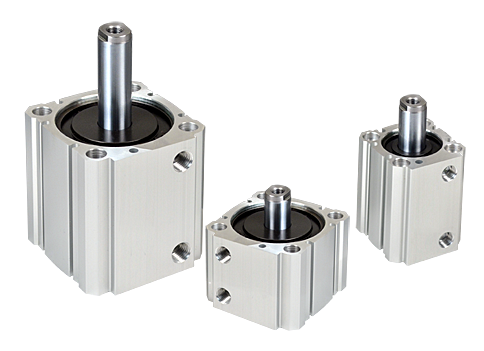

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

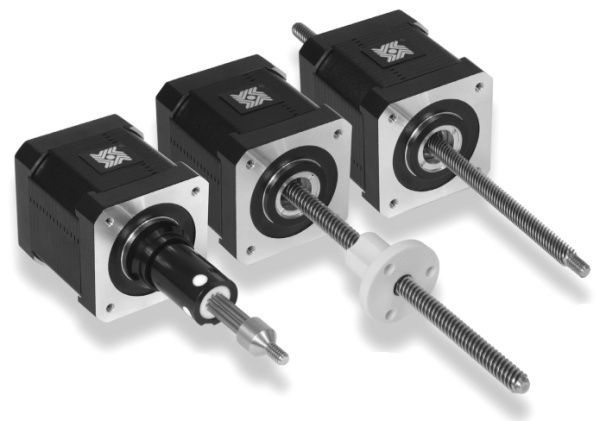

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services