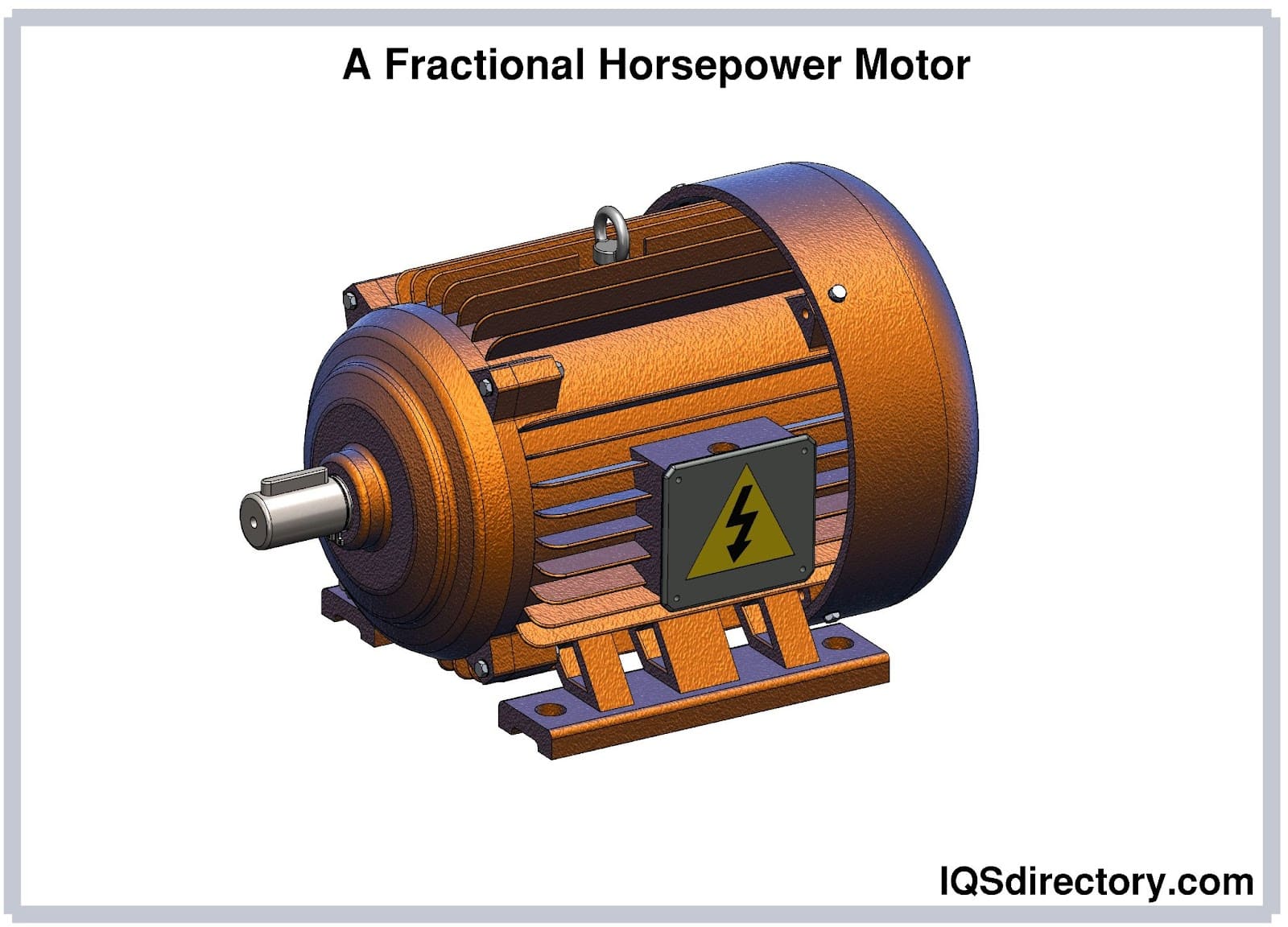

Fractional horsepower motors are small motors that run with a power rating of less than one horsepower, or a fraction of a horsepower. Built on a frame, manufacturers simply refer to fractional horsepower motors as FHP motors. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Carter Motor has over 70 years of experience in quality electric motor manufacturing. Some of the motors manufactured include, AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, along with many others. All of our products are designed and assembled in the United States by our dedicated team of engineers.

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Fractional Horsepower Motor Manufacturers

Fractional horsepower motors, often called FHP motors, are a vital category of small electric motors used throughout commercial, industrial, and residential applications. These motors are typically categorized by their frame size and the total fractional horsepower they deliver. For instance, motors with frame sizes of 42, 48, and 56 can still be classified as FHP motors, even if they exceed one horsepower. Generally, to qualify as an FHP motor, a small electric motor must have a power output of 746 watts or less (one horsepower or below). This specific design threshold distinguishes them from larger, industrial-grade motors while ensuring optimal performance for low-power applications.

Applications

Fractional horsepower motors are essential across many industries and daily devices because of their compact size, energy efficiency, and versatility. Their unique ability to deliver reliable power in a small footprint makes them indispensable for various sectors, each demanding precise control, low noise, and minimal maintenance.

- Industrial Automation and Machinery: In the industrial sector, FHP motors drive small machinery and equipment such as pumps, fans, blowers, conveyors, and compressors. Their capacity to provide sufficient power in a compact package makes them perfect for automation systems, assembly lines, labeling machines, and process controls, where repeatable motion and reliability are key. They also play a pivotal role in robotics, packaging equipment, and light-duty production tools, contributing to increased manufacturing efficiency.

- Automotive Systems: In the automotive industry, fractional horsepower motors are crucial for a wide range of vehicle components, including power windows, windshield wipers, seat adjustments, and HVAC systems. Their precise speed control and compact design enhance the convenience, comfort, and safety of modern vehicles. FHP motors also support electric mirrors, sunroof mechanisms, and fuel pump systems, contributing to the overall functionality of passenger and commercial vehicles.

- Medical Devices: The medical field relies heavily on FHP motors for devices like infusion pumps, blood analyzers, dental equipment, and patient beds. Their low power consumption, reliability, and quiet operation are especially valuable in healthcare environments, where equipment must be both precise and unobtrusive. FHP motors are integral to ventilators, imaging devices, prosthetic devices, and laboratory automation systems, supporting advanced patient care and medical research.

- HVAC Equipment: Fractional horsepower motors are essential in the HVAC (Heating, Ventilation, and Air Conditioning) industry, powering system components such as fans, compressors, blowers, and air handlers. Their energy efficiency and adaptability to varying loads are crucial for maintaining effective temperature control and ventilation in residential, commercial, and industrial spaces. FHP motors help optimize air quality, reduce energy consumption, and improve indoor comfort.

- Consumer Electronics & Appliances: In the consumer electronics market, FHP motors are widely used in home appliances such as refrigerators, washing machines, vacuum cleaners, kitchen mixers, and dishwashers. Their compact size and low noise output make them highly suitable for household devices, where space efficiency and user comfort are key priorities. These motors also power electric fans, food processors, and personal care devices like electric shavers and toothbrushes.

- Aerospace and Aviation: Fractional horsepower motors are utilized in aerospace and aviation industries for powering small actuation systems, flight control surfaces, and robotics. Their lightweight and robust performance make them ideal for the demanding requirements of aircraft and spacecraft, where efficiency and reliability are paramount.

- Renewable Energy and Green Technologies: FHP motors are increasingly found in emerging applications such as solar trackers, small wind turbines, and automated greenhouse systems, where their efficiency and adaptability contribute to sustainability and energy savings.

Explore common questions:

- What are the most popular applications for fractional horsepower motors?

- How do FHP motors improve energy efficiency in HVAC systems?

- Which industries benefit most from compact electric motors?

In summary, fractional horsepower motors are integral to many industries due to their reliability, efficiency, and compact design. They are essential in industrial machinery, automotive systems, medical devices, HVAC equipment, consumer electronics, aerospace, and aviation. As technology evolves, these motors’ applications will likely broaden further, fostering innovation and boosting efficiency across various fields.

History

The evolution of the fractional horsepower motor is intertwined with the history of electric power and automation. Nikola Tesla invented the induction motor, a fundamental technology behind fractional horsepower (FHP) motors, in 1888. Although Tesla’s invention paved the way for electric motor development, the widespread use and production of FHP motors did not gain momentum until 1915, coinciding with the expansion of electric utilities in urban areas. Among the first consumer applications were washing machines, which utilized FHP motors to automate household chores and improve daily life.

The rapid integration of FHP motors into various appliances led to remarkable proliferation: by 1920, over 500,000 functioning FHP motors were operating across the United States. This early adoption helped drive innovation in the appliance, manufacturing, and automotive industries, making automation more accessible to businesses and consumers alike.

After World War II, the FHP motor manufacturing industry experienced significant growth as demand for consumer goods soared. The motors’ compactness and cost-effectiveness made them ideal for powering a new generation of electrical appliances and industrial tools. Since then, the need for these environmentally friendly, energy-efficient motors has continued to expand. Today, FHP motors are integral to automotive systems, power tools, small machinery, industrial robots, and a wide array of household appliances. Their practicality has ensured their enduring popularity. By 2017, experts valued the European FHP market at approximately 4.5 billion USD, highlighting both global demand and the motors’ critical role in modern industry.

Design Considerations for Fractional Horsepower Motors

When designing or choosing a fractional horsepower motor, manufacturers and buyers must evaluate several key factors to ensure the best match for specific applications. These include:

- Power Output and Horsepower: Horsepower measures the amount of work a motor can accomplish over a specific period. FHP motors are designed to deliver up to 746 watts (one horsepower) or less, making them suitable for light- to moderate-duty tasks.

- Torque Specifications: Torque is the measure of the rotational force a motor generates. Selecting a motor with the right torque is crucial for applications requiring precise movement or load handling.

- Speed and Speed Control: In this context, speed refers to the rate at which the motor rotates. Speed variability and reversibility are vital for processes that require frequent direction changes or variable speeds, such as conveyor belts, mixers, and robotics.

- Acceleration and Duty Cycle: Consider whether the motor needs to accelerate quickly from powered down to full power, and how often it will run (continuous vs. intermittent duty).

- Bearing Selection: Bearings are chosen based on application weight, speed, and torque requirements. Common types include ball bearings (for handling heavy axial loads), sleeve bearings (for smooth, quiet operation), and needle bearings (for high-speed applications).

- Enclosure Type: Enclosures shield the motor from external factors such as corrosion, impact, moisture, and chemicals. Options include open drip-proof (ODP), totally enclosed fan cooled (TEFC), and explosion-proof enclosures, depending on application and environment.

- Mounting and Space Constraints: The mount style (foot mount, flange mount, etc.) and overall motor dimensions must be compatible with the equipment and installation environment.

- Power Supply Requirements: Manufacturers powering FHP motors typically opt for single-phase AC power supplies, although AC three-phase and DC power options are also available. Voltage and frequency selection should consider regional requirements (for example, 120V/60Hz in North America, 230V/50Hz in Europe and Asia).

- Thermal Protection and Safety: Thermal protection is a critical feature designed to shut off the motor when it reaches a specified temperature, just below the point of overheating. Common protection mechanisms include manual reset switches and automatic reset switches, safeguarding the motor and extending its lifespan.

- Brush Type or Brushless Design: Deciding between brushed and brushless configurations affects maintenance, lifespan, and noise levels. Brushless motors tend to be more durable and require less maintenance.

- Compliance with Standards: FHP motors adhere to standards set by the National Electrical Manufacturers Association (NEMA), IEEE, and other global organizations to ensure quality, compatibility, and safety.

Manufacturers can tailor features such as voltage, phase configuration (including three-phase or single-phase motors), power supply, and motor frequency to specific application needs. Customization options make FHP motors highly adaptable across a wide range of industries and environments.

Looking to select the right FHP motor?

- What are the key design factors for choosing a fractional horsepower motor?

- How do you match torque and speed requirements to your application?

- What enclosure types are best for harsh or hazardous environments?

Features of Fractional Horsepower Motors

FHP motors typically include a rotor or rotating shaft, a stator, a field magnet, a coil, an axle, and a protective enclosure. These components work together to deliver efficient, reliable performance for light- and medium-duty applications. While some FHP motors are powered by fuel, the majority operate on electricity—either AC or DC. In some advanced models, magnetic power sources enhance performance and efficiency.

Electric power enables FHP motors to operate with variable speeds and reversible gears. As universal electric motors, many FHP motors can run on both alternating current (AC) and direct current (DC), increasing their versatility. To generate power, FHP electric motors utilize electromagnetic principles—magnets within the motor interact with electrical current, creating motion and torque.

Other notable features include:

- Low noise operation, making them ideal for residential and medical settings

- High efficiency and low energy consumption, supporting sustainability

- Compact and lightweight designs for easy integration into tight spaces

- Robust construction for long service life and minimal maintenance

- Advanced speed and torque control options for precision tasks

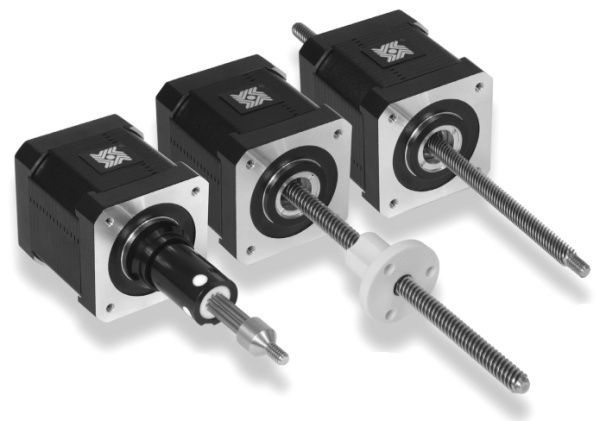

Types of Fractional Horsepower Motors

The variety of FHP motor types available enables engineers and designers to select the optimal solution for every application, from simple devices to complex automation systems. Key categories include:

- Small electric motors: Consuming up to 745.7 watts of power, these motors are renowned for their durability and reliability. They typically feature two battery leads, a cylindrical enclosure, an axle, and a nylon end cap.

- ½ HP motors: FHP motors operating at approximately 373 watts (half of one horsepower), suitable for medium-duty tasks in appliances or machinery.

- ¼ HP motors: Delivering one-quarter of a horsepower (about 186 watts), these motors are ideal for lightweight, precision-driven applications.

- AC motors: Powered by alternating current, these motors can use induction or synchronous methods and are common in appliances, HVAC systems, and automation equipment.

- DC motors: Powered by direct current, these motors offer easy speed adjustment and are favored in battery-operated devices, robotics, and portable tools.

- Variable speed FHP motors: These allow for precise control over motor speed, making them ideal for applications where motion accuracy is critical.

- Brushless FHP motors: More expensive due to the need for external power supplies, but they offer longer life, reduced maintenance, and quieter operation.

- Fuel-powered FHP motors: These internal combustion engines generate power using fuel (gasoline or diesel) via exhaust valves and a fuel chamber, suitable for portable or remote applications.

- Permanent magnet motors: Utilize permanent magnets in their rotor assemblies to deliver increased power, improved torque efficiency, and eliminate slip. While offering superior performance, their cost is higher due to rare earth materials.

- FHP induction motors: Employ electromagnets and a modulated stator coil to create a rotating magnetic field, delivering reliable and efficient motion.

- FHP single-phase motors: Popular due to their affordability, efficiency, and reliability, these operate on single-phase AC power and are suitable for most household and light industrial uses.

- FHP gearmotors: Integrate a motor with a gear head to slow down speeds and increase torque for use in conveyors, lifts, and automated doors.

- Sub-fractional motors (micro motors): Extremely compact FHP motors found in medical devices, toys, small gadgets, and precision instruments.

Curious about FHP motor types?

- What are the differences between AC, DC, and brushless FHP motors?

- Which type of fractional horsepower motor is best for robotics?

- How do gearmotors improve automation system performance?

Advantages of Using Fractional Horsepower Motors

Fractional horsepower motors face competition from larger industrial motors and emerging motion technologies. However, they offer several distinct advantages that make them the preferred choice for many applications.

- Energy Efficiency: FHP motors use less power, which saves energy costs and supports green building initiatives. Their low power consumption makes them environmentally friendly and cost-effective over the lifespan of a system.

- Compact Size and Lightweight Design: Their small footprint allows for easy integration into space-constrained devices and machinery, increasing product design flexibility.

- Reliability and Durability: FHP motors are engineered for long life and require minimal maintenance, making them a smart investment for manufacturers and end-users.

- Versatility: These motors are used in a diverse range of applications—from household appliances and medical equipment to automotive systems and industrial automation—demonstrating their adaptability.

- Ease of Installation and Use: Straightforward mounting options and standardized designs make installation quick and accessible, even for non-experts.

- Cost-Effectiveness: Competitive pricing and low operating costs appeal to both OEMs and end-users seeking to manage budgets without compromising on quality.

- Precision and Consistency: FHP motors deliver repeatable performance and high accuracy, critical for automated systems and devices requiring consistent output.

Manual labor and alternative actuation technologies such as piezoelectric actuators and magnetic levitation systems offer unique benefits for specialized use cases, but FHP motors remain dominant for general automation and consumer products due to their balance of cost, performance, and ease of use.

Comparing options?

- Why choose a fractional horsepower motor over a larger industrial motor?

- How do FHP motors reduce total cost of ownership?

- What makes FHP motors ideal for medical and automation devices?

In conclusion, fractional horsepower motors are an outstanding option when higher horsepower motors, manual labor, or other technologies aren’t ideal. Their efficiency, reliability, versatility, and cost-effectiveness make them the go-to choice for numerous applications, ensuring their ongoing popularity in the market.

Accessories for Fractional Horsepower Motors

Fractional horsepower motors gain enhanced performance and usability through a variety of accessories designed to maximize operational efficiency and extend lifespan. Common FHP motor accessories include:

- Couplings: Connect the motor shaft to other rotating components, ensuring smooth power transfer and compensating for misalignments.

- Motor Bases and Adaptor Bases: Provide stable mounting platforms and allow for flexible alignment with driven equipment, minimizing vibration and optimizing performance.

- Brush Holder Caps: Protect brush holders in DC motors from contaminants, ensuring consistent electrical current and reducing maintenance needs.

- Rectifiers: Convert AC power to DC, enabling precise speed control and reversibility for a broader range of applications.

- Dust Covers: Shield internal components from dust and debris, preserving efficiency and preventing premature wear or damage, especially in challenging environments.

- Brakes: Deliver precise stopping or holding capabilities, critical for applications requiring quick deceleration or stable positioning.

- Foot Mounts: Securely attach the motor to machinery frames or housings, improving installation stability.

Selecting the right accessories depends on factors such as motor type, speed control needs, environmental conditions, and compatibility with the driven equipment. Consulting with motor experts or engineers can help identify the most effective accessory solutions for specific applications.

Need help sourcing FHP motor accessories?

- What accessories are essential for your FHP motor application?

- How do you enhance motor longevity with the right add-ons?

- Where can you find high-quality FHP motor accessories?

To obtain these accessories, individuals can contact local motor dealers, distributors, and industrial suppliers. Many manufacturers specializing in motor-related products make these accessories available on their websites or online marketplaces. Consulting with motor experts or engineers can offer valuable guidance in selecting the most appropriate accessories for specific applications, helping to ensure optimal motor performance and longevity.

Industry Standards for Fractional Horsepower Motors

In the United States and globally, several key organizations establish standards for fractional horsepower motors, ensuring safety, efficiency, and consistent performance. The National Electrical Manufacturers Association (NEMA) is a leading authority, defining guidelines, performance criteria, and best practices for FHP motors. NEMA standards cover aspects such as design, materials, testing procedures, and efficiency ratings.

Other prominent organizations include the Institute of Electrical and Electronics Engineers (IEEE) and the American National Standards Institute (ANSI). These groups contribute to the broader framework governing electric motor safety, interoperability, and environmental responsibility.

Complying with these standards is crucial for:

- Ensuring motors meet rigorous quality and performance benchmarks

- Guaranteeing safe operation and minimizing risks of electrical hazards, such as fire and shock

- Improving energy efficiency and reducing environmental impact

- Streamlining the replacement process and ensuring compatibility with existing equipment

- Facilitating regulatory compliance and avoiding legal complications

Using non-compliant FHP motors can result in safety risks, increased operational costs, reduced productivity, and potential legal or insurance issues. Conversely, selecting motors that meet or exceed established standards provides peace of mind, lower maintenance costs, and a longer service life.

Researching compliance?

- How do NEMA, IEEE, and ANSI standards affect FHP motor selection?

- What are the consequences of using non-compliant motors?

- How can you verify a motor’s compliance before purchasing?

In summary, organizations such as NEMA, IEEE, and ANSI establish crucial standards for fractional horsepower motors in the United States and globally, providing vital guidelines for manufacturers, consumers, and regulators. Adhering to these standards ensures safety, efficiency, and consistent performance. Motors that do not comply may pose safety risks, operate inefficiently, and incur higher operational costs. Choosing fractional horsepower motors that meet these established standards offers advantages including energy savings, reliability, regulatory compliance, and compatibility, making them the preferred option for various applications.

Things to Consider When Purchasing Fractional Horsepower Motors

No matter the type of fractional horsepower motor you use, its performance is only as reliable as the manufacturer or supplier you choose. With a wide variety of FHP motor manufacturers and distributors in the market, finding the right partner can seem overwhelming. To simplify the process, we’ve compiled a list of trusted, experienced fractional horsepower motor manufacturers for your consideration. Their detailed profiles are available between these informational paragraphs.

Tips for Selecting the Best FHP Motor Supplier:

- Define Your Specifications: Before contacting suppliers, draft a comprehensive list of your requirements, including power rating, voltage, torque, speed, mounting style, enclosure type, duty cycle, environmental conditions, and any required certifications or standards.

- Research and Shortlist: Review the profiles of recommended manufacturers and select three or four that align closely with your application and quality requirements.

- Request Quotes and Compare: Solicit detailed quotes from your shortlisted suppliers. Compare pricing, lead times, technical support, warranty terms, and value-added services such as customization or post-delivery assistance.

- Engage in Detailed Discussions: Clarify your needs with each supplier, including budget, timeline, compliance requirements, delivery preferences, and after-sales support. Ask about their experience with similar projects and their ability to provide references.

- Evaluate and Choose: Assess the responses and select the supplier that offers the best blend of quality, value, expertise, and support for your specific application.

Ready to find the right fractional horsepower motor manufacturer?

- What are the most important factors in choosing an FHP motor supplier?

- How can you ensure your motor meets application-specific needs?

- What questions should you ask before making a purchase?

Taking the time to carefully evaluate your options will help ensure that you receive a high-quality, reliable fractional horsepower motor that meets your current and future needs—whether you’re upgrading manufacturing equipment, building new automation systems, or designing innovative consumer products.

Frequently Asked Questions About Fractional Horsepower Motors

What is the difference between fractional and integral horsepower motors?

Fractional horsepower motors are designed for outputs of one horsepower (746 watts) or less, making them ideal for low- and medium-duty applications. Integral horsepower motors provide more than one horsepower and are used for heavy-duty industrial applications requiring greater power and torque.

How do I determine the right size FHP motor for my application?

Consider the load requirements, duty cycle, ambient environment, and available power supply. Consult with manufacturers and use application calculators or engineering support to select an appropriately rated motor that meets all performance and safety requirements.

Are brushless FHP motors better than brushed ones?

Brushless motors typically offer longer lifespans, reduced maintenance, and quieter operation, making them suited for applications where reliability and low noise are priorities. However, brushed FHP motors can be more cost-effective and are suitable for simple, budget-sensitive uses.

What maintenance is required for FHP motors?

Routine maintenance may include bearing lubrication, checking electrical connections, cleaning enclosures, and inspecting for wear or overheating. Brushless designs often require less maintenance than brushed models.

Can FHP motors be customized for unique requirements?

Yes, many manufacturers offer customization options such as shaft configuration, voltage, mounting, enclosure, and integrated gearheads. Custom FHP motors can be engineered to match precise application needs.

What are the most common problems with FHP motors?

Common issues include overheating, bearing failure, electrical faults, and contamination from dust or moisture. Selecting the right enclosure, using proper accessories, and adhering to maintenance schedules can minimize these problems.

Contact and Consultation

Ready to start your project or need expert guidance? Contact us for personalized assistance in choosing the best fractional horsepower motor for your unique requirements. Our team of experienced engineers and industry specialists is here to answer your questions, provide technical resources, and help you optimize your equipment for peak performance and efficiency.

Continue learning:

- Browse more FHP motor manufacturers

- Learn about FHP motor types and technologies

- Explore universal electric motors

- Discover permanent magnet motor advantages

Empower your next automation, appliance, or precision device project with the right fractional horsepower motor—engineered for efficiency, reliability, and innovation.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services