A tiny electric motor is an example of an electromechanical device that converts electrical energy into mechanical energy. The motor’s output energy is used to move materials, power compressors, and rotate fans. Electric motors are powered by alternating current sources like electric generators, power grids, inverters, or direct current sources like batteries, rectifiers, and motor vehicles. Read More…

At AutomationDirect.com, we specialize in providing a wide range of electric motors and electronic enclosures to meet our customers' diverse needs. Our commitment to excellence drives us to offer top-quality products that deliver superior performance and reliability. With our extensive selection of electric motors, ranging from AC motors to DC motors and everything in between, we empower...

When reliability and power are a must, the universal motors you find at ElectroCraft can operate with high efficiency, low voltage, and at a low cost. Applications that our universal electric motors serve include robotics, packaging, automotive, and medical equipment. Electric motor products include the CompletePower™ Plus Universal Drive, complete with a user-friendly configurable interface....

Carter Motor has over 70 years of experience in quality electric motor manufacturing. Some of the motors manufactured include, AC universal motors, small motors, DC universal motors, DC permanent magnet motors, DC shunt wound motors and gearmotors, along with many others. All of our products are designed and assembled in the United States by our dedicated team of engineers.

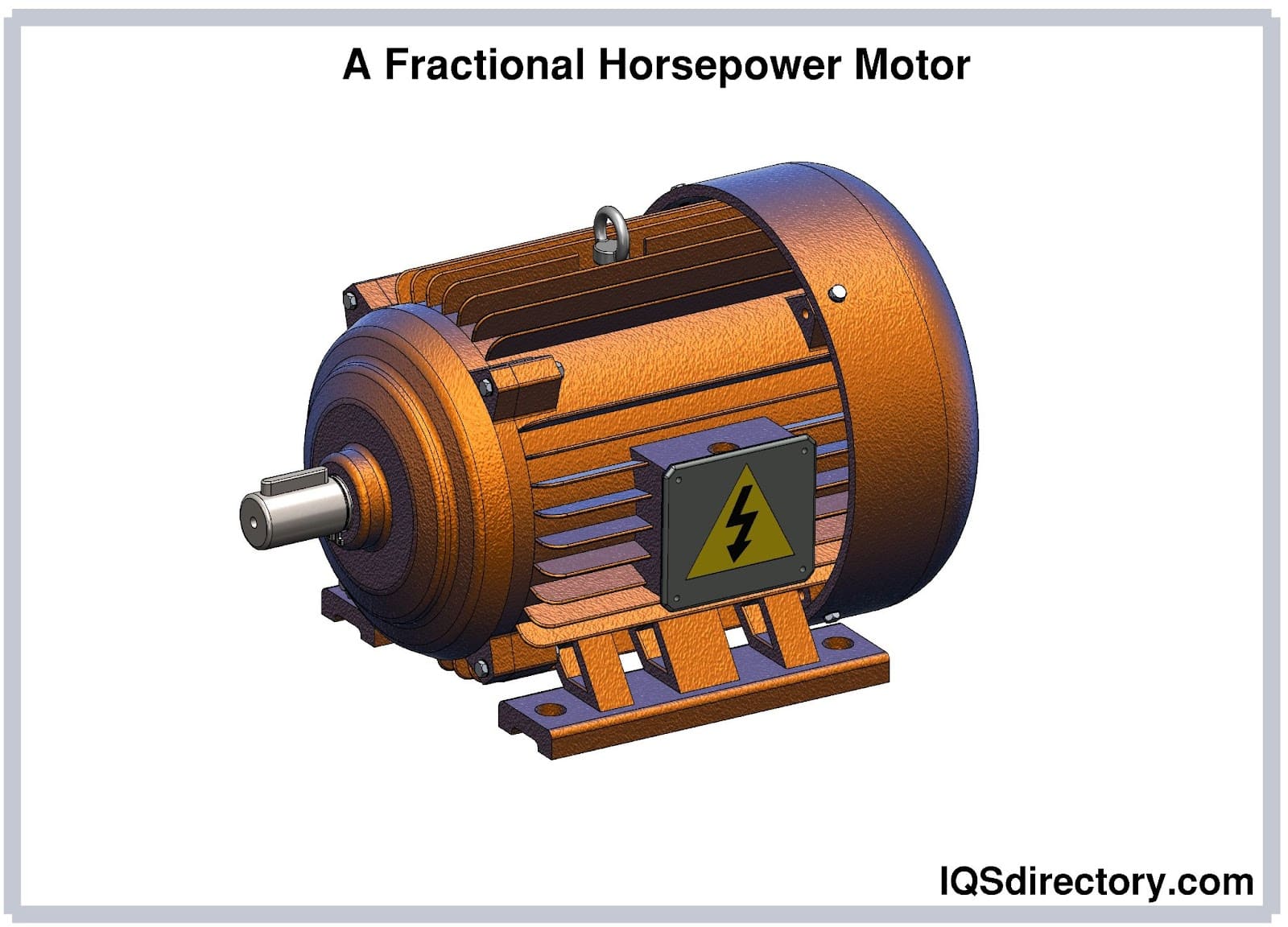

When you choose Composite Motors, you gain access to a reliable and forward-thinking partner in the realm of fractional horsepower motors. Our products are designed to endure, ensuring that your systems operate at their best for years to come. Join us in embracing the power of innovation and quality, as we continue to shape the future of fractional horsepower motors together.

More Small Electric Motor Manufacturers

Components of Electric Motors

Electric motors, including small electric motors and fractional horsepower motors, are comprised of several essential components that work together to convert electrical energy into mechanical energy. Understanding the anatomy of an electric motor helps buyers, engineers, and decision-makers evaluate which motor designs best match specific applications, whether in industrial automation, consumer electronics, or automotive systems. The key parts of both AC and DC motors include the rotor, stator, air gap, windings, commutator, and bearings.

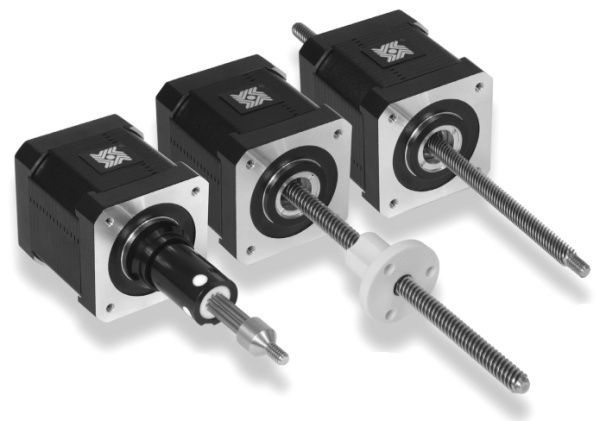

Rotor

The rotor is the rotating part of an electric motor, generator, or alternator. It is responsible for transferring the conversion of electrical energy into mechanical motion, which drives a shaft to generate useful work. Inside a motor, the rotor contains conductors—typically copper or aluminum bars—arranged to carry current and interact with the stator's magnetic field. As the rotor spins, the interaction between the electromagnetic fields and the windings produces torque at the rotor axis. The design and balance of the rotor are critical for minimizing vibration and maximizing efficiency and service life.

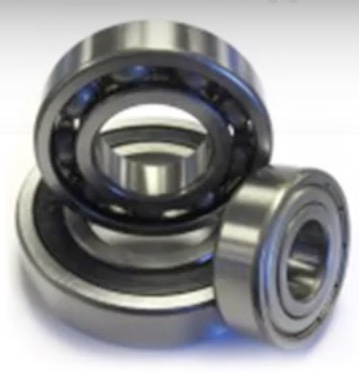

Bearings

Bearings are vital to electric motor operation, supporting the rotor and enabling smooth, low-friction rotation around its axis. High-quality bearings reduce wear, increase the lifespan of the motor, and help accommodate both radial and axial loads. In applications involving overhung loads—where forces are applied to the shaft beyond the bearing support—proper bearing selection and alignment are crucial to prevent premature failure.

Stator

The stator is the stationary component of the electric motor, housing windings or permanent magnets that generate a rotating magnetic field. In AC motors, the stator is typically made from laminated steel cores and copper windings to reduce eddy current losses. In DC motors, permanent magnets or electromagnetic windings form the stator. The stator's construction and materials directly influence the motor's efficiency, output torque, and thermal performance. Applications demanding high torque density or precise control, such as robotics or electric vehicles, often rely on optimized stator designs.

Air Gap

The air gap is the physical space between the stator and rotor. Though small, the air gap plays a significant role in the performance of electric motors. A minimal air gap improves efficiency by strengthening the magnetic field but increases manufacturing complexity. Conversely, a wider air gap may simplify assembly but usually results in higher magnetizing current and reduced efficiency. Proper air gap sizing is essential for high-performance electric motors used in precision drives, servos, and fractional horsepower applications.

Windings

Windings are insulated copper or aluminum wires arranged into coils, embedded within the stator or rotor. When electrical current passes through the windings, it induces a magnetic field, which interacts with other motor components to produce rotational motion. The quality, configuration, and insulation of windings affect the motor’s power output, efficiency, and temperature rise. Motors designed for continuous-duty cycles or high-load environments—such as industrial conveyors or HVAC blowers—often use premium copper windings to ensure reliability and longevity.

Commutator

The commutator is a rotary electrical switch, primarily found in brushed DC motors. It reverses the direction of current flow between the rotor and the external circuit, ensuring unidirectional torque. Constructed as a segmented cylinder of copper, the commutator works in tandem with stationary carbon brushes to maintain electrical contact as the motor spins. While commutators are essential for many DC motor designs, brushless motors use electronic controllers to achieve the same effect, offering advantages in maintenance and lifespan.

How Small Electric Motors Function

Small electric motors operate based on the principle of electromagnetic induction. When a current-carrying conductor (such as a loop of wire) is placed within a magnetic field, it experiences a force that causes rotational motion. In most small motors, the loop is positioned between the poles of a magnet, and the ends are connected to a power source, such as a battery for DC motors or an AC supply for AC motors. This interaction between the magnetic field and current creates a turning force—torque—that spins the rotor, translating electrical energy into mechanical energy.

For those interested in the technical details, the working principle of electric motors is deeply rooted in Faraday’s law of electromagnetic induction. This foundational principle is essential for understanding the behavior of both small and fractional horsepower electric motors in practical applications.

Small Electric Motor Types

Small electric motors come in a range of configurations, each optimized for specific power sources, physical constructions, and intended uses. When selecting a motor for an application—whether it's for robotics, HVAC systems, home appliances, or industrial automation—it's important to understand the differences between the main types. The most common categories include:

- Small AC Electric Motors: Powered by alternating current, these motors are ideal for consistent speed and reliable operation in household appliances and industrial equipment.

- Small DC Electric Motors: Powered by direct current, DC motors offer variable speed control and high starting torque, making them suitable for battery-operated devices and precision motion systems.

- Brushless Motors: These use electronic controllers instead of commutators and brushes, leading to less maintenance and longer lifespans. Widely used in drones, electric vehicles, and medical devices.

- Brushed Motors: Traditional DC motor design employing brushes and commutators. Often found in cost-sensitive or simple control applications like toys, small tools, and some automotive systems.

- Single-phase and Three-phase Motors: Single-phase motors are commonly used in small loads and household equipment. Three-phase motors provide higher efficiency and are prevalent in industrial applications.

- Air-cooled and Liquid-cooled Motors: Cooling methods are critical in high-power or continuous-duty uses. Liquid-cooled motors are often employed in high-performance electric vehicles and industrial machinery.

Wondering which type of electric motor is best for your project? Explore the different small electric motor types to match your application's voltage, size, torque, and speed requirements.

Small AC Electric Motors

Small AC electric motors convert alternating current into mechanical motion using electromagnetic induction. Their design typically includes a stationary stator and a rotating rotor, working together to generate a rotating magnetic field. Small AC motors are further divided into single-phase and three-phase variants:

- Single-phase AC Motors: Often found in small appliances, fans, and pumps, these motors are valued for simplicity and cost-effectiveness. They are best suited for light-duty applications where efficiency and power requirements are moderate.

- Three-phase AC Motors: Used in industrial and commercial settings, these motors offer superior efficiency, starting torque, and durability. They are ideal for high-power applications such as compressors, conveyors, and machine tools.

Advantages of small AC motors include low maintenance, long operational life, and reliable performance under varying loads. When evaluating AC motors for purchase, consider factors such as voltage compatibility, enclosure type, frame size, and efficiency ratings.

Small DC Electric Motors

A small DC electric motor is a compact rotary device that converts direct current electrical energy into mechanical motion. These motors are popular in applications requiring precise speed control, rapid acceleration, and high starting torque. Typical uses include robotics, automotive accessories (such as power windows and windshield wipers), portable tools, and battery-powered devices.

DC motors can be subdivided into:

- Brushed DC Motors: Employ brushes and commutators for current switching. Simple, cost-effective, but require periodic maintenance.

- Brushless DC Motors (BLDC): Use electronic controllers for commutation, resulting in quieter operation, higher efficiency, and reduced maintenance. Widely used in drones, electric vehicles, and high-reliability medical devices.

Small Electric Motor Advantages

- Cost-Effective Power: Small electric motors are more affordable than engines powered by fossil fuels, with comparable horsepower (hp) ratings for many applications.

- Long Lifespan: Electric motors have fewer moving parts compared to combustion engines, leading to longer operational life and reduced maintenance needs.

- Automation Capability: Electric motors can be easily integrated into automated systems, enabling precise control and repeatability for manufacturing or robotics.

- Energy Efficiency: Modern electric motors, especially brushless and high-efficiency AC motors, offer superior energy conversion and lower operational costs.

- Low Environmental Impact: Electric motors produce no direct emissions, making them ideal for sustainable and green technology initiatives.

- Compact Design: Small and fractional horsepower motors are lightweight and space-saving, which is essential for portable electronics, medical devices, and compact machinery.

Uses for Electrical Motors

Small electric motors are ubiquitous in modern technology, powering a vast array of products and systems. Their versatility, reliability, and scalability make them essential in numerous industries. Typical applications include:

- Industrial Automation: Used in rolling mills, compressors, fans, blowers, pumps, turbines, and paper mills for process control and material handling.

- Consumer Electronics and Appliances: Essential components in devices such as washing machines, dryers, refrigerators, vacuum cleaners, and power tools.

- Automotive Industry: Small motors drive power windows, seats, mirrors, HVAC systems, windshield wipers, fuel pumps, and electric power steering.

- HVAC (Heating, Ventilation, and Air Conditioning): Motors power fans, blowers, and compressors essential for climate control in residential, commercial, and industrial settings.

- Robotics and Automation: Fractional horsepower motors are vital for actuators, servos, and precise motion control in robotic arms, drones, and automated guided vehicles (AGVs).

- Medical Devices: Used in pumps, respirators, diagnostic equipment, and prosthetics where reliability and precision are critical.

- Material Handling: Found in forklifts, winches, hoists, conveyors, and other equipment that move goods in warehouses and factories.

- Renewable Energy: Small motors are used in tracking systems for solar panels and in wind turbine pitch and yaw mechanisms.

Small Electric Motors: Key Decision Factors

Selecting the right small electric motor for your application involves careful consideration of several technical and commercial factors. Here are the main aspects to evaluate:

- Power and Torque Requirements: Define the load demands and ensure the motor can deliver the necessary torque at desired speeds.

- Voltage and Current: Match the motor's electrical specifications with your power supply—AC or DC, single-phase or three-phase.

- Size and Mounting: Assess available installation space and select a frame size and mounting style compatible with your equipment.

- Operating Environment: Consider temperature, humidity, exposure to dust, and the need for waterproof or explosion-proof enclosures.

- Control Method: Decide between simple on/off switching, variable speed drives, or advanced electronic controllers.

- Duty Cycle: Determine if the application is intermittent, continuous, or requires frequent starts and stops.

- Efficiency and Regulatory Compliance: Look for high-efficiency ratings and certifications such as NEMA, IEC, or UL to meet safety and energy standards.

- Budget and Total Cost of Ownership: Consider not only purchase price but also installation, maintenance, and operating costs over the motor’s life.

Need help with motor selection? Ask our experts: What is the best small electric motor for my industrial, commercial, or consumer application?

Choosing the Proper Small Electric Motor Manufacturer

Choosing a reputable small electric motor manufacturer is essential for obtaining reliable, high-performance motors tailored to your project requirements. The right supplier offers technical support, customization options, and competitive pricing to ensure you achieve optimal results. To streamline your search, use our directory of vetted small electric motor manufacturers.

- Review business profile pages to assess experience, capabilities, certifications, and product offerings.

- Compare manufacturers based on lead times, quality control, and after-sales support.

- Use our proprietary website previewer to quickly evaluate each company’s specialization—whether in custom fractional horsepower motors, high-efficiency designs, or specific industry applications.

- Reach out directly via our contact forms to request detailed information, specifications, or a competitive quote.

- Submit a single RFQ form to contact multiple suppliers simultaneously, saving time and maximizing your options.

Before making a purchase, consider asking these search-driven questions:

- What certifications or standards does your electric motor meet (NEMA, IEC, UL, etc.)?

- Can the motor be customized for specific voltage, mounting, or enclosure requirements?

- What is the typical lead time for orders, and do you offer technical support during installation or integration?

- Are there sample or prototype options available for evaluation?

- What warranty and after-sales services are included?

For a deeper dive into comparing suppliers, visit our guide to choosing small electric motor manufacturers or use our RFQ form to get started.

Frequently Asked Questions About Small Electric Motors

- What is the difference between AC and DC small electric motors?

AC motors are powered by alternating current, offering consistent speed and low maintenance, while DC motors are powered by direct current, featuring variable speed and high starting torque. Brushless DC motors (BLDC) are increasingly popular for their efficiency and reliability. - How do I size a small electric motor for my application?

Consider the load, required speed, torque, power supply, duty cycle, and physical constraints. Use motor sizing calculators or consult with an expert for precise recommendations. - What are common causes of electric motor failure?

Overheating, poor lubrication, misalignment, excessive loading, electrical surges, and inadequate maintenance are leading causes. Selecting the right motor and following recommended maintenance practices can minimize downtime. - Can small electric motors be repaired or serviced?

Yes, many electric motors can be repaired, including bearing replacement, rewinding, and commutator servicing. Brushless motors generally require less maintenance than brushed types. - Are energy-efficient or eco-friendly motors available?

Yes, high-efficiency and eco-friendly electric motors are available, reducing energy consumption and environmental impact. Look for motors with premium efficiency ratings and RoHS compliance.

Explore, Compare, and Connect

Ready to find the ideal small electric motor for your needs? Explore our small electric motor directory to view top suppliers, compare technical specifications, and connect with manufacturers for custom solutions or bulk orders.

Still have questions? Reach out to our team for expert advice on selecting, sourcing, or integrating small electric motors into your next project.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services